Net Zero success stories from the industry

There are many examples of decarbonisation projects within the European paper sack and sack kraft paper industry. Whether from the point of view of the whole industry, individual member companies or on a product level – the efforts show the industry’s commitment to initiate meaningful change.

Continuous improvement of CO2 footprint of paper sacks

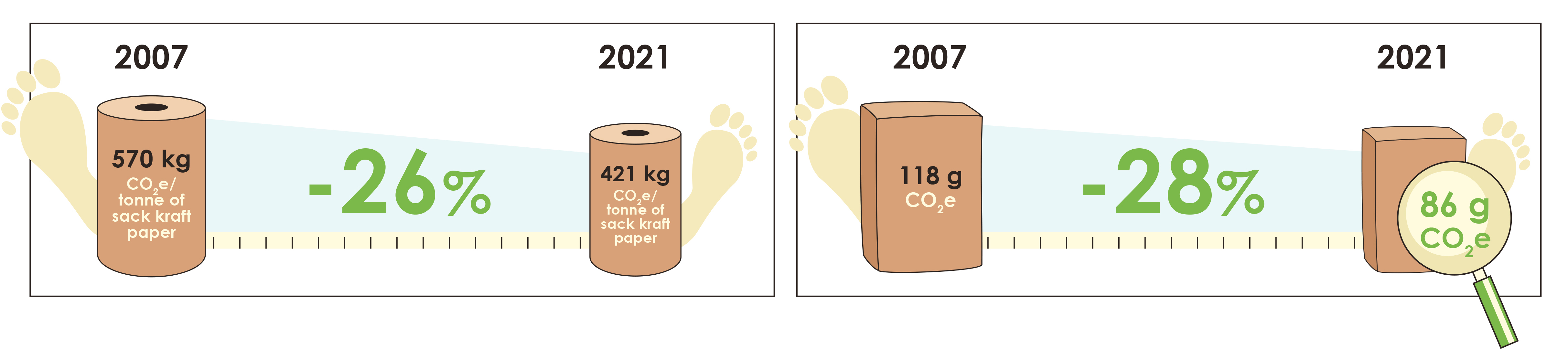

Between 2007 and 2021, the carbon footprint figures of the European paper sack and sack kraft paper industry show an impressive improvement:

- There is a significant reduction in fossil carbon impact per tonne of sack kraft paper of approximately 26% – from 570 kg CO2e to 421 kg CO2e. The reasons for that are predominantly fewer emissions from net purchased grid electricity and from the combustion of fuels consumed by the mills.

- Per paper sack, the figures show a 28% improvement – from 118 g CO2e per sack in 2007 to 86 g CO2e per sack in 2021. It can be attributed to reductions in sack weight and in fossil fuel consumption.

Construction Goes Circular alliance

To close the loop and support a circular economy for paper sacks in Spain, stakeholders from the European paper sack industry launched the Construction Goes Circular alliance. Focusing initially on paper sacks for building materials, the initiative has brought together over 70 companies and 180 construction sites – including manufacturers, construction firms, waste managers, recyclers and industry associations. The alliance aims to boost recycling volumes for a range of construction materials, including paper sacks, gypsum, insulation, plastics and wood. By keeping materials in the loop, the initiative helps to reduce emissions – not only for the European paper sack industry, but also in the construction sector.

Joint innovation for low-carbon solutions

The film producer W. Gröning and sack kraft paper and paper sack manufacturer Billerud developed the Future-Proof Paper Sack for Low-Carbon Cement. The solution combines ultra-breathable and semi-extensible sack kraft paper with an 8 µm HDPE film containing 35% PCR to meet future PPWR regulations. The sack combines materials that are already available on the market to achieve high strength and moisture protection with a reduced carbon footprint compared to conventional options. Moreover, the sack allows dust-free, high-efficiency filling of finer, low-carbon cement blends which are expected to become increasingly common. For their joint project, the companies were presented with the Silver Grand Prix Award 2025.

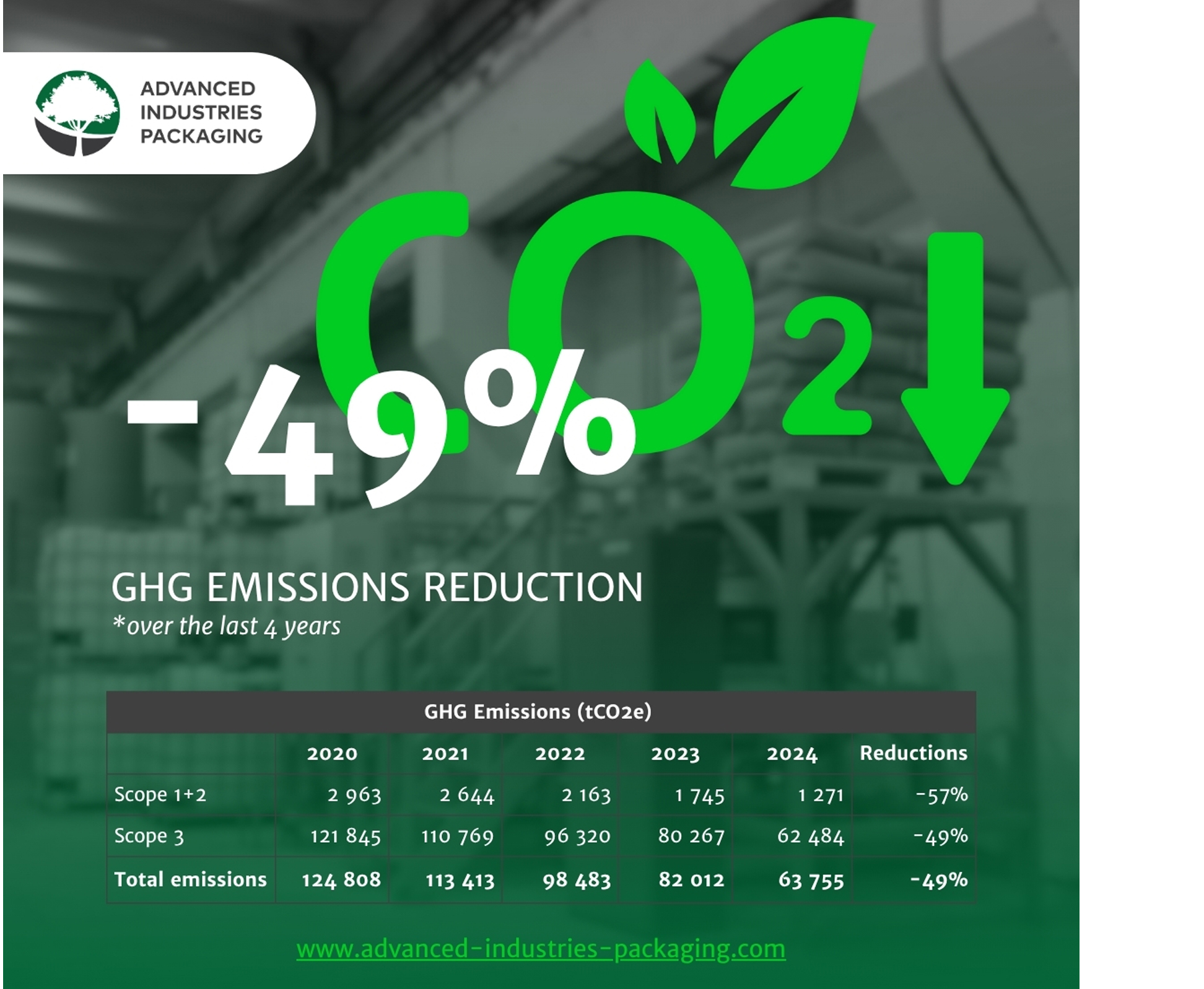

Paper sack producer records impressive CO2 reductions

Between 2020 and 2024, Advanced Industries Packaging, AIP, reduced its Scope 1 and 2 emissions by 57% and total GHG emissions by 49%. Among others, these achievements can be attributed to:

• switching to wind energy at one site

• adjusting the energy mix

• introducing electric and hybrid forklifts and vehicles production

• optimising operational processes

• responsible sourcing of raw materials

• specific developments in paper sack construction and design

Solar energy drives decarbonisation

Corazza is advancing on its net zero pathway with investments in renewable energy and efficiency. In 2024, the company installed a 2-megawatt photovoltaic system which operates across all its facilities. It produced more than 1.9 million kWh of renewable electricity, supplying around 27% of the company’s annual energy demand and contributing to a renewable energy share of more than 50%. Additional efficiency measures such as energy recovery from production processes, a shift to LED lighting and modernised combustion systems have significantly reduced the company’s fossil fuel consumption. Adding to that, Corazza increased the recyclability of its packaging, among others by increasing the recyclable share of plastics from 13% in 2023 to 22% in 2024. To further drive emissions reductions where it is most relevant, the company is in the process of getting more granular data on the corporate carbon footprint.

From family hands to a low-carbon future

Family-owned Gil Escoin launched its 2022–2025 sustainability plan with the installation of a photovoltaic station. In parallel, the company introduced electric vehicles for internal and external logistics. These measures reduced the carbon footprint by 2.4 kg CO₂ per 1,000 units and delivered around 20% energy savings compared with the previous situation. The facility is in a region strongly committed to decarbonisation, where one of Europe’s largest coal plants was recently decommissioned and replaced by renewable sources such as photovoltaic, biomass and wind. In this context, the family business actively contributes to the energy transition.

Progress against GHG reduction targets

In 2024, Mondi reduced its scope 1 emissions by 210,000 tonnes CO2e and their scope 2 emissions by 30,000 tonnes CO2e compared to 2023. This 11% reduction in their absolute scope 1 and 2 emissions can mainly be attributed to the following measures taken at different operations:

• energy efficiency improvements

• turbine upgrades and replacements

• switch to lower-carbon fuels

• increase share of sustainable biomass and biofuels as part of this shift and

• purchase of green electricity.

Emissions cuts ahead of schedule

In 2024, Billerud reported a 33% reduction in Scope 1 and 2 emissions – 337,000 tonnes of CO2e compared to 2022. This puts the company ahead of schedule, covering 78% of the reductions needed to meet its near-term climate targets for 2030. Early procurement of fossil-free electricity at two sites contributed 79,000 tonnes in 2024. Operational improvements, efficiency gains and volume changes accounted for another 164,000 tonnes.

Renewables expansion delivers real cuts

Starkraft/Heinzel Pöls focuses on sustainable and responsible production along the entire value chain. Recent actions have delivered measurable results:

• Since 2021, the company has achieved a reduction of 28% of Scope 1 and 2 emissions. This change was driven by increased use of alternative biogenic fuels, continuous investments in energy efficiency measures and process optimisation (such as innovative evaporator technology).

• Today, 92% of the site’s energy comes from renewable sources – achieved with a combination of biomass (utilisation of black liquor and tall pitch), hydropower, photovoltaics, heat exchangers, etc.

• More than 75% of wood utilised is sourced locally in Austria.

• Excess energy produced by Heinzel Pöls supplied around 16,000 households in the vicinity with district heating and electricity in 2024.

Driving decarbonisation in Brazil

Since 2022, Klabin has reduced its Scope 1 and 2 emissions by 13.2% and its Scope 3 emissions by 17.4%. This progress was driven by investments in biomass boilers, gasification plants, and the replacement of fossil fuels with renewable alternatives. Today, 93% of the company’s energy matrix is renewable, supported by biomass, black liquor, other renewable fuel technologies and International Renewable Energy Certificates (I-RECs; for purchased energy). Klabin also applies an internal carbon price per tonne of CO₂, ensuring that climate costs are considered in all major investment decisions. By introducing climate-performance-based compensation for employees which ties 20% of the performance-based pay to achieving the company’s sustainability targets, the company clearly links the daily operations to decarbonisation efforts.