More information

Industry Guidelines Dust-free paper sacks (English)

Industry Guidelines Dust-free paper sacks (French)

From better health and safety conditions via easy handling, resource- and cost-effective production to a positive brand image – dust-free paper sacks offer many benefits. By paying special attention to the clean packaging of paper sacks, the product protection offered by paper sacks can even be raised further.

Ultrasonic sealing for higher product protection

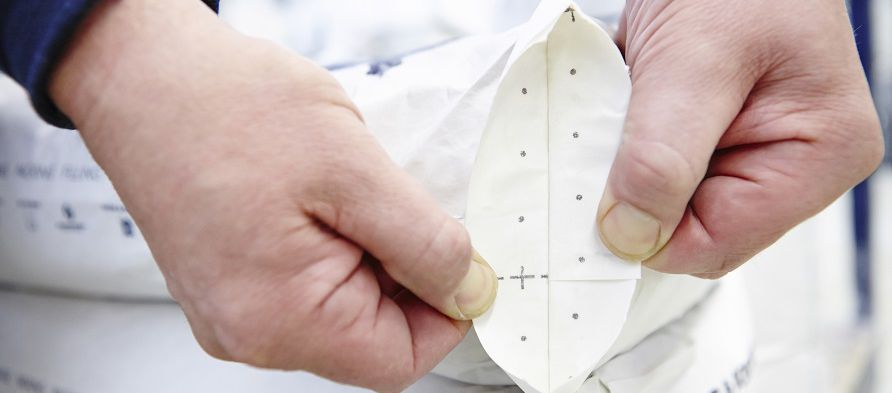

The ultrasonic sealing technique ensures that paper sacks will not be contaminated during the filling process and no product loss or dust nuisance will occur on the way from the filler to the customers. It is applicable for valve sacks which are equipped with a short outside valve and a sealable coating on the inner valve. After the filling process, the valve is welded by a tool that is attached to each of the filling machine’s spouts: this ultrasonic closing head pneumatically swivels downward and welds the coated paper valve. This process does not considerably prolong the overall filling speed and results in absolutely tightly sealed and clean sacks.

Further advantages of ultrasonic sealing: thanks to the self-cleaning effect of the weld zone, no subsequent cleaning systems are required. This allows fillers to save on plant parts such as spillage and dust collection systems as well as cleaning sets. Moreover, the improved cleanliness leads to lower wear of plant parts and reduced maintenance costs. Since less cleaning and de-dusting equipment is needed, the energy costs are reduced as well.

Besides ultrasonic sealing, there are other measures and actions relevant for achieving a high degree of product protection.

Industry Guidelines Dust-free paper sacks (English)

Industry Guidelines Dust-free paper sacks (French)