Towards net zero: a shared vision for the European paper sack industry

The European paper sack and sack kraft paper industry has taken an important first step in addressing climate change. In line with the European Union’s target of achieving climate neutrality by 2050, the industry has committed to developing a net zero pathway – a strategic road map that outlines the collective steps needed to decarbonise the industry. The net zero initiative is a joint project of the European Paper Sack Research Group (ESG), a collaboration between EUROSAC and CEPI Eurokraft. It unites stakeholders at multiple stages of the paper sack value chain. This includes sack kraft paper producers, sack converters and manufacturers of adhesives, films and machinery. Establishing a net zero pathway highlights the importance of addressing emission reductions through collective action as no single actor can achieve net zero on their own.

The pathway aims at establishing common levers for emissions reductions, set meaningful targets and provide a structured approach that enables all stakeholders – regardless of where they are on their individual decarbonisation journey – to align their efforts. Through collaboration, the industry will foster a transparent, consistent and science‑based approach towards reaching net zero that benefits industry stakeholders and customers alike.

This vision is clear: to reduce the industry’s collective climate impact to net zero by 2050, support paper sack customers in meeting their sustainability targets and contribute to the decarbonisation of the European economy. While the pathway is still under development, the industry is confident that collective knowledge, collaboration and a shared ambition can lay the groundwork for meaningful progress towards a climate‑neutral future.

“Sustainability has always inspired innovation in our industry, and the development of a net zero pathway will encourage collaboration and drive us to continuously improve both our environmental impact and our packaging solutions for our customers. Together, we can lay the foundation for real change across the entire paper sack value chain.”, according to Alessandro Selmin, EUROSAC president.

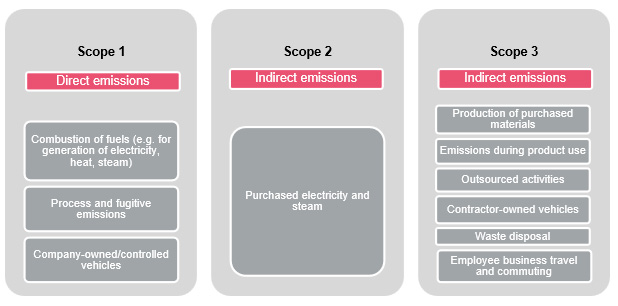

Classification of activities for carbon reduction

The Greenhouse Gas (GHG) Protocol provides global standards for measuring and managing greenhouse gas emissions across operations and value chains. The net zero road map covers the three emissions scopes defined by the GHG Protocol. The classification of activities into scopes is made from the perspective of an organisation, and the scopes are related to the source and type of emissions.

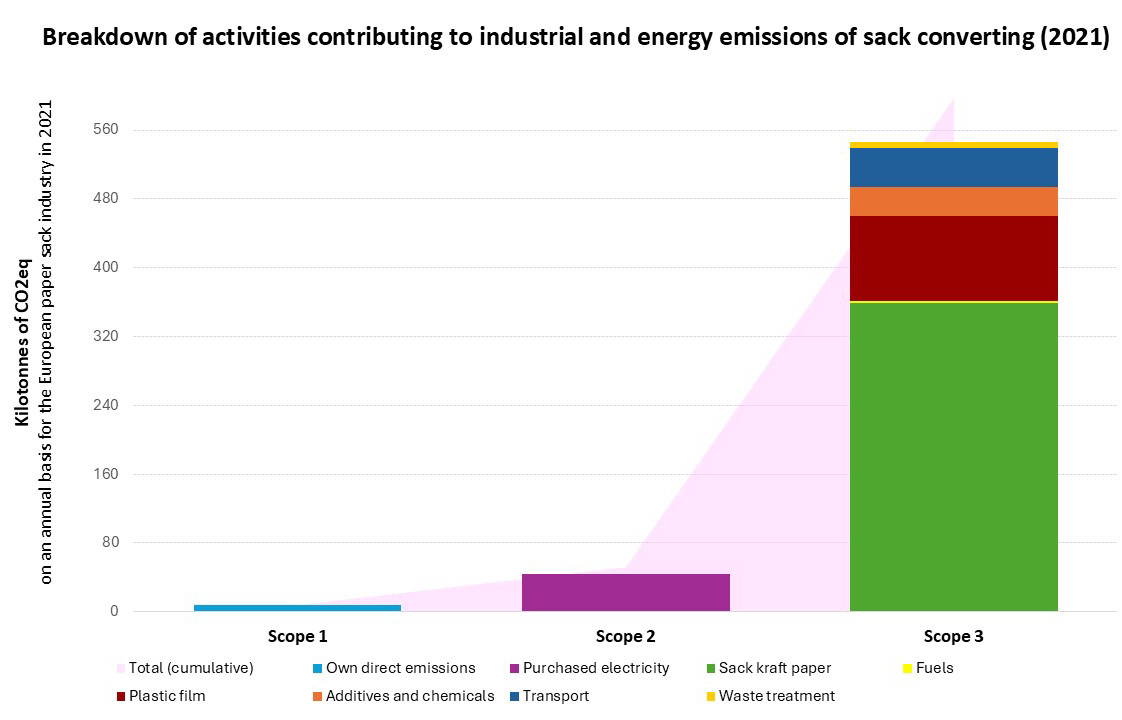

From footprint to action: key areas for reducing emissions

The current fossil footprint of paper sacks highlights where emissions mainly occur – and where the industry has the biggest opportunities to reduce them. Scope 3 dominates the picture, with sack kraft paper, polyethylene (PE) films, inks and transport standing out as key levers for decarbonisation.

Scope 1: Direct emissions

Scope 1 emissions are relatively low for paper sack producers as direct emissions from paper production fall under Scope 3. Reductions of Scope 1 emissions can be achieved by increasing energy efficiency and switching to cleaner energy sources such as biofuels, solar, wind or hydropower at production sites.

Scope 2: Indirect emissions from purchased electricity

These emissions can be reduced by purchasing electricity from low-carbon or renewable sources.

Scope 3: Indirect emissions from value chain

Scope 3 emissions are responsible for most of the European paper sack industry’s carbon footprint. Sack kraft paper production accounts for 60% of total emissions and 66% of Scope 3 emissions. Other significant contributors include PE film, truck transportation and printing inks. By sourcing lower-emission materials and services and through strong collaboration across the paper sack value chain, the industry has the opportunity to make significant progress in cutting emissions together.

Priority areas for decarbonisation

One of the key priorities for sack kraft paper producers is the implementation of no-deforestation commitments. This is particularly relevant considering the EU’s new European Deforestation Regulation (EUDR) and the increasing demand for transparency in material sourcing and due diligence practices. While many producers do not own the forests where their raw materials originate, they are nonetheless responsible for ensuring that the pulp they purchase does not contribute to deforestation. Verifiable supply chain practices and clear environmental standards are therefore essential to align with regulatory requirements and to support net zero goals.

Transitioning to renewable energy is a key decarbonisation lever for both sack kraft paper producers and paper sack manufacturers. By sourcing electricity and heat from certified renewable sources such as biofuels, wind, solar or hydropower, companies can significantly reduce their Scope 1 and 2 emissions and lower the carbon footprint of their operations. Several technologies are available, such as electric or biomass boilers, heat recovery systems and hybrid configurations. This switch supports compliance with climate targets and improves the environmental profile of the entire value chain.

Improving energy efficiency is a key decarbonisation priority for sack kraft paper producers and converters, particularly in energy-intensive processes such as drying, pulping and steam generation. The first and most effective step is to reduce energy demand through improved efficiency as it lowers consumption, cuts costs and avoids emissions before energy sourcing even comes into play. Energy storage solutions, such as electrical or thermal storage, can further support decarbonisation by enabling more efficient use of renewable electricity, reducing peak demand and increasing operational flexibility. Together, these measures strengthen the sustainability performance across the entire value chain.

Optimising transport is an important lever for reducing emissions in the paper sack and sack kraft paper value chain. Key measures include shortening delivery routes, improving load efficiency and switching to vehicles with lower emission classes. Replacing diesel- and gasoline-powered vehicles with electric trucks or vans can significantly cut transport-related emissions when charged with electricity from renewable sources such as wind, water or solar. For longer distances or heavier loads, green hydrogen-powered vehicles are an emerging low-emission option. In addition, intermodal transport solutions that combine road, rail and sea can further reduce the environmental impact of logistics.

Improving material efficiency is another relevant pathway to lower emissions across the value chain. Producers can reduce their climate impact by optimising chemical use in production (e.g. adhesives, inks, additives and coatings), improving material yields and reducing process waste. At the same time, innovations such as the development of high-strength sack kraft paper with reduced basis weight or material-saving design can support emissions reductions by ensuring optimised product protection without excessive packaging. Close collaboration with sack kraft paper, film and other suppliers remains key to driving further efficiency gains and achieving shared sustainability targets.

Certain materials used in paper sack production, such as fossil-based plastic films used for barrier properties, have a high-carbon footprint. Replacing these with low-carbon alternatives is an important step toward reducing emissions. Key focus areas include bio-based films and films from recycled materials, replacing films with coatings for applications with lower barrier requirements, as well as reducing the carbon footprint of auxiliary products purchased, such as printing inks, starches, glues, additives and process chemicals. As a first step, the industry will need to work on improving data availability on the emissions associated with these purchased goods and services, laying the groundwork for more targeted decarbonisation efforts.

End-of-life management plays a vital role in reducing carbon emissions and advancing a more circular use of materials. Increasing recycling rates for paper sacks requires the establishment of dedicated sorting and collection systems and collaboration across the value chain – from users and waste management companies to recyclers. By closing the material loop, the industry can lower emissions and contribute to the circular bioeconomy.

Discover success stories from the industry

There are many examples of decarbonisation projects within the European paper sack and sack kraft paper industry. Whether from the point of view of the whole industry, individual member companies or on a product level – the efforts show the industry’s commitment to initiate meaningful change.